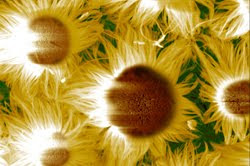

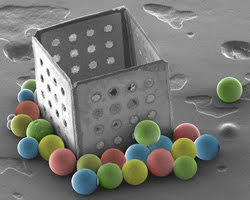

These first two pictures of science imitating art are my favourites from the series. We are able to see these pictures due to the magic of the Scanning Electron Microscope (SEM). The "Field of Sunflowers" were produced by S.K. Hark, Chinese University of Hong Kong and won 1st prise in the 2008 sprint meet. The Second image was produced by Wen Hsun Tu, National Taiwan University, Taipei, Taiwan and titled "Nano-Witch" was the 2nd Place Winner in the 2009 fall meeting.

Both images are composed of what is known as nanowires. Each nanowire is about 10 nm in diameter and tens of micrometers in length. They were grown from a silicon oxide (SiOx) compound for the sunflowers and a zink oxide (ZnO) for the nano-witch. Both use a process known as Vapour-Liquid-Solid (VLS) to grow the nanowires.

Both images are composed of what is known as nanowires. Each nanowire is about 10 nm in diameter and tens of micrometers in length. They were grown from a silicon oxide (SiOx) compound for the sunflowers and a zink oxide (ZnO) for the nano-witch. Both use a process known as Vapour-Liquid-Solid (VLS) to grow the nanowires.The process starts with the compound, either SiOx or ZnO which is heated sufficiently to turn it into a vapour. Once in vapour form, it will want to condense. Catalysts, small nano structure particles, are used to control where the condensation takes place.

The vapour condenses into liquid around these catalysts and starts to crystallise around and under the catalyst due to the supersaturation of the silicon or zink in the condensed droplet (I think). Thus the growth shape is influenced by the shape of the catalysts. The crystals continue to grow in this condensation and crystallisation process, pushing the catalyst upward and along and continually building the nano wire underneath.

The crystallisation process is similar to what you see if you supersaturate water with salt. I.e salt crystals will grow. The difference is that the nanowires are surrounded by tempreatures anywhere from 500-1000 degrees Celsius, give or take a few hundred degrees.

With out the catalysts, the nano wires could grow anywhere and in any shape under a different process known as Vapour-Solid or VS. The VLS method gives more precise control over the geometry and location of the nano wires. Although, having said that, I don't know why the second image turned out so random apparantly using the same controlled process. Hmmm. I guess forget everything I just said and blame my source.

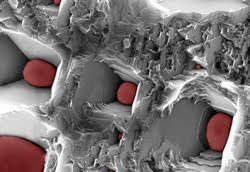

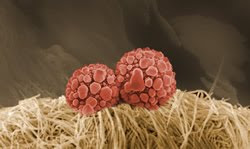

Now, I just missed the Bledisloe Cup because I was writing this blog. My feet are near numb and it's getting harder to type due to the cold. Now it's time for you to indulge in the remaining nano structure pictures.

Thank you Materials Research Society!

No comments:

Post a Comment